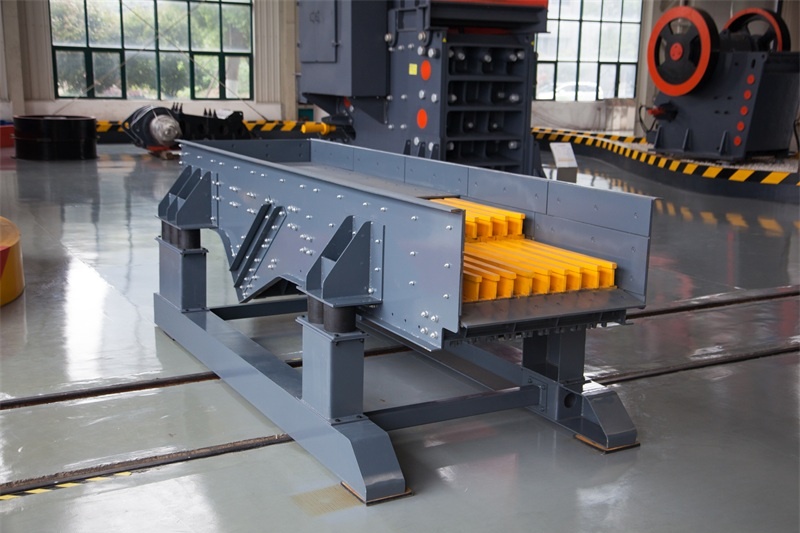

GF Vibrating Feeder - High Efficiency Primary Feeding Equipment

15 11,2024

Zhengzhou MiningAlliance Machinery Co.,LTD.

Tutorial Guide

Discover the GF Vibrating Feeder, a highly efficient primary feeding equipment designed for mobile crushing stations and small-sized hoppers. With a feeding capacity of 280-450 tons per hour and advanced features, it enhances material handling and improves processing efficiency.

Introduction

The GF Vibrating Feeder is a powerful primary feeding equipment ideal for mobile crushing stations and small-sized hoppers. Engineered for efficiency, it can handle a variety of stone materials such as granite, marble, basalt, limestone, quartzite, pebbles, copper ore, and iron ore, with a feeding size of up to 700 mm and a processing capacity of 280-450 tons per hour.

Advantages

- 4.0G Vibration Intensity: This feature enhances the conveying capacity and significantly improves the pre-screening effect.

- 20% Enhanced Processing Capability: Equipped with dual-layer screening, effectively eliminating 90% of fine materials below the discharge outlet's gap.

- Robust Rubber Springs: Offering greater load capacity and a longer lifespan compared to traditional metal springs.

- Stable Operation: Low noise levels and minimal foundation impact, with precision-manufactured critical components ensuring high quality.

Working Principle

Driven by a vibrating motor, the GF Vibrating Feeder creates vibrations that move materials towards the discharge end. This motion facilitates preliminary separation due to the gaps between the bars, ensuring uniform particle sizes. Fine materials smaller than the bar gaps are filtered out, allowing larger pieces to be directed towards the crushers.

Applications

The GF Vibrating Feeder is designed for seamless integration with jaw crushers, primary impact crushers, and hammer crushers. It is specifically suitable for stable material feeding and preliminary separation across various crushing equipment.